- Elkem

- Mobility & transportation

- Parts manufacturing

Parts manufacturing

We contribute to the creation of stronger and more durable vehicle parts

We provide the strength and support your vehicle needs with our high-quality metallurgical parts

Ferrosilicon for special steel

Enhancing manufacture of special steels using high-purity ferrosilicon

The term ‘special steel’ encompasses a wide range of steel grades, and usually refers to products with a higher proportion of alloying elements, or with tailored properties for niche applications. We understand the important role that ferrosilicon (FeSi) plays in achieving these specifications, and our specialists are ready to help you choose the right product.

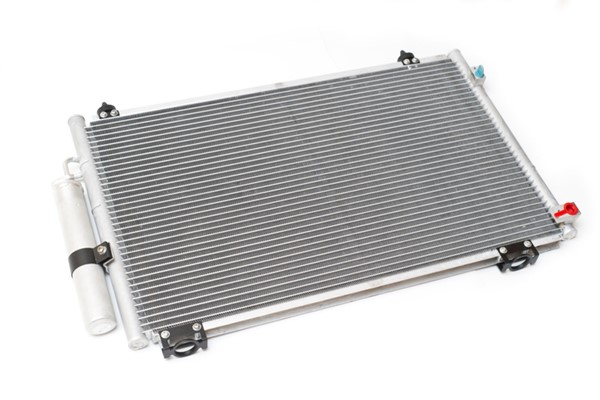

Silicon for aluminium brazing used in vehicle functional parts

Homogeneous silicon for more efficient brazing

Aluminium brazing using a non-ferrous silicon-based flux is faster and provides a better finish than traditional gas soldering. We take care to ensure high homogeneity in our silicon brazing product, for high-quality results in every case.

Foundry alloys for compacted ductile iron used in crankshaft

Controlling spheroidal graphite formation with foundry alloys

Ductile iron is a versatile material that has grown in popularity over recent decades, due to its excellent mechanical properties and castability. For these reasons, ductile iron castings are the preferred choice in many sectors, including wind energy, engineering and automotive industries.

Silicon for aluminium alloying in vehicle parts

Improving the properties of aluminium in critical transport applications

Silicon plays a crucial role in the manufacture of aluminium vehicle parts, being commonly alloyed with it to enhance its mechanical properties. We supply nearly all the grades of metallurgical silicon you’re likely to need, and are ready to listen to your requirements.

Foundry alloys for train bogies and suspensions

Reinforcing train part components for efficient railway transportation

Foundry alloys are essential for train bogies and suspensions. They offer high strength, durability, and resistance to wear and fatigue. These alloys reinforce components like wheels, axles, brakes, suspension arms, couplers, and spring assemblies, supporting heavy loads, enduring dynamic forces, and improving ride quality. Their reliability makes them crucial for safe and efficient railway transportation.

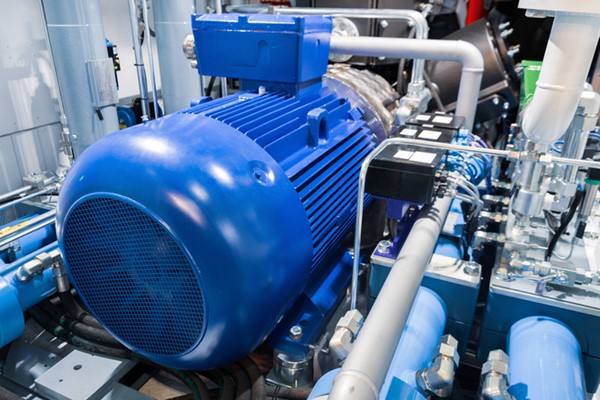

Foundry alloys for pneumatics

Foundry alloys are crucial in pneumatics, enabling high-quality components for pneumatic systems.

These alloys provide exceptional strength, durability, and corrosion resistance needed for demanding conditions. Used in valves, cylinders, pistons, and fittings, they allow intricate designs and precise manufacturing, ensuring optimal performance and efficiency. Their reliability significantly enhances the functionality of pneumatic systems, maintaining consistent air pressure, controlling fluid flow, and enabling smooth actuation.

Foundry alloys for pump manufacturing

Enhancing overall performance and durability in pump manufacturing

These alloys are chosen for specific properties crucial in various pump components. They offer exceptional strength, corrosion and wear resistance, ensuring reliable operation in tough conditions. Their versatility allows intricate designs, optimizing pump efficiency and reducing energy loss. From impellers to casings, shafts, and bearings, foundry alloys serve as essential elements for robust and efficient pump systems.

Ferrosilicon for steel

Improving quality and performance of steels using ferrosilicon alloys

We provide the flexibility and durability your vehicle needs with our reliable elastomeric parts

Silicone rubber used in elastomeric vehicle parts

Improving the ability to withstand extreme conditions

The growing trend for smaller engine compartments leads to higher temperatures and more stress on vital parts – and this is where high-consistency rubber (HCR) and liquid silicone rubber (LSR) have an important role to play.

Silicone rubber for railway parts

Enhancing resistance to heat, fire and mechanical stress

Regulations for rolling stock emphasize the need for heat- and fire-resistant materials, and other applications in the railway sector demand high mechanical performance. Our silicone rubbers meet these specifications, and in many cases are now the material of choice.

Industrial silicone sealant for railways

Solutions for railway rolling stock, from initial assembly to maintenance, repair and overhaul

Train and rolling stock manufacturers have been among the most innovative players in the transport industry, constantly seeking to improve their offer so that it meets travelers’ expectations for safe and efficient transport. Our silicone gels, foams, adhesives and thermally conductive products provide answers to the challenges encountered while doing this, from initial assembly through to maintenance, repair and overhaul.

Industrial assembly: Sealing and bonding applications

High-quality standard silicones for industrial assembly and electronics protection

Assisting the production of lightweight and durable composite parts

Reusable silicone vacuum bags for composite molded parts used in transportation

Silicone reusable vacuum bags (RVBs) for better composite infusion molding applications

Fiber-reinforced polymer (FRP) composites are increasingly being used to make molded parts for a wide variety of industries, including automotive, renewable energy, aerospace, marine construction, and architecture. These composites combine excellent mechanical properties with a low density, and feature high resistance to water, chemical and environmental pressure.

Silicones for thermal expansion molding of composite parts used in transportation

Silicones enable accurate and cost-efficient expansion molding processes for composite materials

Composites, also known as composite materials, are fiber-reinforced resins or polymers intertwined in matrices, which are molded in expansive thermosetting processes to produce lightweight and highly resistant parts and structures.

Silicone release coatings for composite liners used in aircraft manufacturing

Streamlining production of composite automotive parts

Silicone pressure-sensitive adhesives (PSAs) are commonly used by composite manufacturers in the automotive industry, and provide an instant bond with excellent resistance to heat, chemicals and UV radiation. As well as improving production efficiency, they make it possible to easily remove a part without leaving a residue, which is useful during the assembly process.

Composite Molding with silicone reusable vacuum bag

An innovative alternative to improving molded parts quality while lowering serial production costs

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.