- Elkem

- Media

- News articles

- New Product Launch Additive Manufacturing 2024

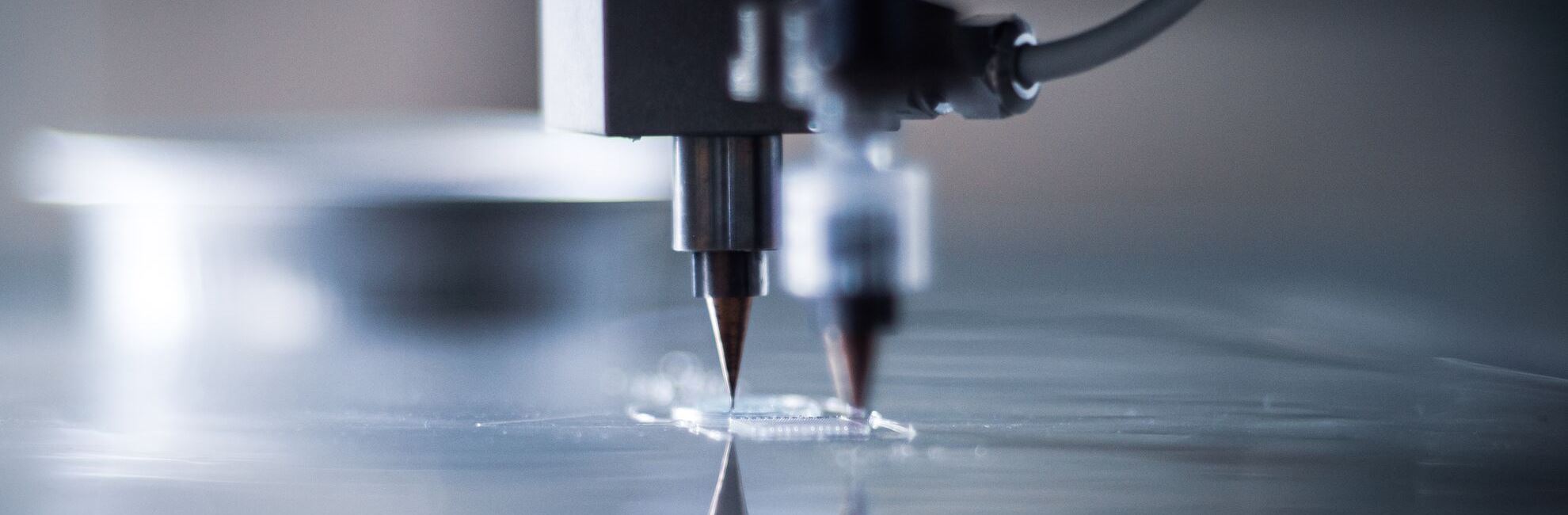

A new generation of silicone elastomers specifically designed for additive manufacturing

Longer shelf life and improved productivity are the advantages of this new silicone elastomers for Additive Manufacturing!

The AMSil™ 20503 series is an advanced development for Additive Manufacturing (AM) / 3D Printing applications based on tailored Liquid Silicone Rubber (LSR) formulations. This range offers the production of durable and functional components, such as spare parts, anatomical models, and textiles…

AMSil™ 20503 series provides a multitude of benefits:

- Enhanced productivity thanks to finetuned rheology

- Extended shelf life

- Close development with 3D Printer manufacturers &

end-users - High physicochemical performances and durability

These formulations are available with Shore A hardness from ShA 5 to ShA 70, maintaining the well-known properties of 100% silicones for LDM (Liquid Deposit Molding) based systems.

Additionally, Elkem is introducing the AMSil™ 92102, a new reference in the support material series.

AMSil™ 92102 provides a multitude of benefits:

- Improved printability

- Allowing refined surface aspects

- Enable more complex and efficient structures.

These advancements highlight Elkem’s commitment to driving the Additive Manufacturing/3D Printing sector forward and contributing to a more sustainable economy. By scaling Additive Manufacturing/3D Printing to industrial levels through Digital Manufacturing, Elkem aims to create innovative, profitable, and sustainable solutions that reduce waste, transportation, and storage costs, thereby lowering the carbon footprint of end-products.

AMSil™ 20503 series - AMSil™ 92102

New Generation of Silicone Elastomers specifically designed for Additive Manufacturing with longer shelf life and improved productivity.

Sustainability at Elkem

To learn more about our sustainability initiatives, check our webpage.

Contact us

Take your business to the next level by partnering with a world-leading material manufacturer.